Clean rooms. Food safety systems

Optimal safety in food and beverage production

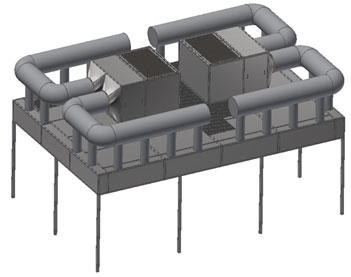

Airpurtec® advanced particle filtering systems for clean rooms allow the homologation of high environmental quality in production, handling, packaging or storage areas and avoid problems derived from indoor environmental contamination.

The equipment is manufactured with the highest constructive quality according to international standards and completely in AISI 304 OR AISI 316 stainless steel that withstand the most aggressive environments. We offer high performances based on ISO criteria or other standards required in each type of food room.

In the food industry, working with equipment designed in accordance with a GFSI accepted standard, such as IFS, BRC, FSSC 22000 or SQF, eases the path to future certification and brand reinforcement and demonstrates the commitment of companies to safety. of its products which allows access to potential clients of large national and international distribution centers.

We adapt to the needs of each installation and manufacture tailored systems for all applications, glass and steel or panel insulation enclosures, enclosures with air supply in conveyor belts, UTA (air treatment units) in stainless steel for prefabricated rooms or large warehouses, ...

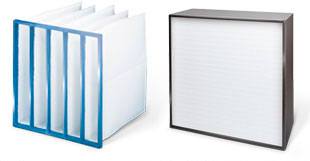

We have an extensive range of Hepa filters, bag filters, carbon filters, pre-filters, ... with different efficiency classifications to adapt to the demands of each type of room, in standard or custom formats, which meet the highest demands.

Our technical department will design the equipment that your installation requires, providing you with the most appropriate solution with the final ISO clean room qualification certificate for the required category.

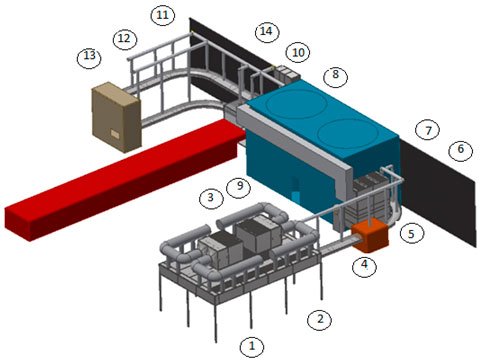

Exclusive laminar flow air cleaning system in food handling packaging rooms without enclosure panels

The exclusive laminar flow particle control system in spaces without enclosure Airpurtec® opens up new possibilities in handling and packaging areas because it makes the mobility of operators and entry and exit flows more flexible since there is no physical enclosure.

With this advanced technology we achieve and certify the same air quality parameters at critical points as in a closed room without the inconvenience of the walls.

We design custom projects with dynamic flow design software for a perfect impulsion of clean and treated air at low speed that ensures optimal working conditions and thermal comfort.

- Laminar flow with air curtain

- Air curtain ventilation and filtration unit

- Air curtain duct

- Conveyor 1

- Conveyor 2

- Chiller Ventilation and Filtration Unit

- Laminar flow chiller duct

- Chiller duct

- Electric control and power panel

- Ventilation and mold release unit